mark

-

Content

1,983 -

Joined

-

Last visited

-

Days Won

2 -

Feedback

0%

Posts posted by mark

-

-

46 minutes ago, pchapman said:Who is behind Parakit Inc., of Georgetown Texas, who copyrighted the Lone Star manual in 1985? Are they still around? Or are relatives still selling the manual or hanging on to it to sell for millions down the road?

Kevin Gibson claims to have the galleys, and he led me to believe the copyright holder is still alive. I couldn't find an email address or phone number for him, and he didn't respond to a snail-mail letter I sent.

You're right: I've not seen a better manual for an intro to sewing for riggers.-

1

1

-

-

3 hours ago, fallingplastik said:Just out of curiosity, is anyone still active to share a new link to download the manual?

The manual is copyrighted.

-

What reasons do they give you for departing from the 30-35 weeks they advertise on their website?

-

1

1

-

-

2 hours ago, wolfriverjoe said:Setting them properly.

This, mostly. Even experienced jumps make mistakes sometimes, especially if they're setting the brakes in the high-distraction environment of the landing area. Pull the brake-set eye below the guide ring before inserting the tongue of the toggle.

The pocket for the toggle tongue can be tightened by running a row of stitches directly on top of the existing pocket stitches. Try along one side before doing both, as the result can be dramatic.

If the bottom of your toggle is secured with a pin, the slot for the pin is exactly 3/16" wide, which is the standard gauge on a double-needle machine. Overstitch the existing stitches. This is easier on some risers than others.

Any moment now, the Racer fans are going to chime in about snaps.

--Mark

-

Yes.

-

34 minutes ago, bdb2004 said:In general, I would be quite happy to pay a premium for jump tickets if it means a lower risk for skydivers in the long term.

How much of a premium would you be quite happy to pay? How much lower would the risk need to be?

-

44745 will require cockpit voice recorders and flight data recorders.

Part 135 pilot requirements include a requirement for check pilots, and oral/practical check rides every 6 months.

See 135.265 for maximum duty time and required rest periods. Someone is going to have to keep training records and duty/rest records.

-

2

2

-

-

35 minutes ago, baronn said:Can this go into service?

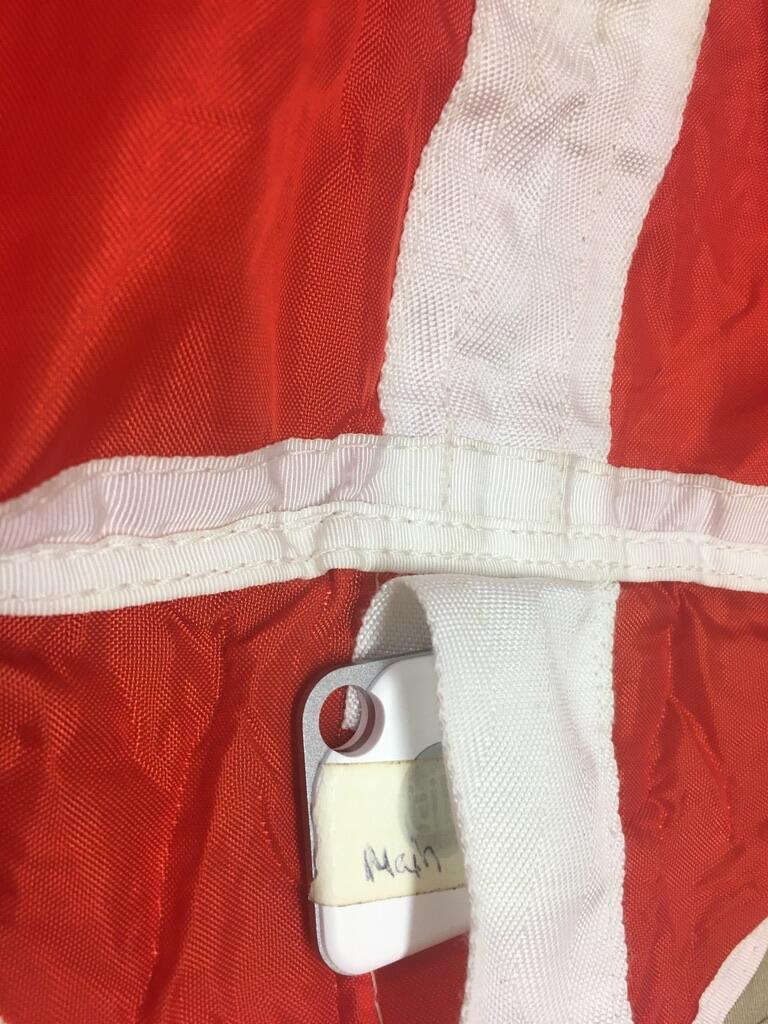

Maybe. The magnetic riser covers are a change to the TSO configuration. Since they cover the reserve risers, they may affect airworthiness. They are an alteration. Did you get approval from the manufacturer or the FAA, or did you just do it?

-

For jumps to count toward USPA licenses, ratings, and awards, they must comply with USPA Basic Safety Requirements -- see Ian Harrop's post.

However, the US FAA does not have a minimum jump altitude or a minimum opening altitude. Note that it is not possible to set a new record for minimum altitude. The best you can do is tie the existing record.

For minimum altitudes for jumps outside the US, check with your local skydiving/aviation authority.

In the US, jumps from Part 103 ultralights (which includes most powered parachutes and paragliders, as well as some gyrocopters) is generally prohibited by the FAA, since the jumper would be a passenger, not a student pilot undergoing flight instruction. Additionally, skydiving from Experimental and Restricted category aircraft is also generally prohibited by the FAA.

-

2 hours ago, lippy said:. . . would the added benefit (the debate on the value of that benefit being alive and well above) be worth the penalty in battery life?

Battery life is not an issue if there is an accessible charging port.

-

A simple collision is unlikely to extract the trigger. Think of how difficult it would be to extract a Cypres control head from its pocket in similar circumstances.

You might be able to extract the trigger if the collision involved snagging the RSL. I can't recall any incidents involving snagged RSLs on any system, so we should consider the probability of this happening to be quite low.

-

1

1

-

-

1 hour ago, race25 said:Be careful packing old US military equipment, most of it has a published service life . . .

In the US, unless a TSO approval states otherwise, a shelf life/service life limitation does not apply to formerly military equipment in civilian use. See AC 105-2E para 13.b.(2).

-

2

2

-

-

I'll give it a try.

Every rigger has the responsibility of declaring airworthiness or non-airworthiness when asked to pack a rig. But his decision is not binding on any other rigger. The owner is free to find someone else to do the work. Caveat emptor! I don't think this is what you are asking though. I think you are asking who can permanently ground a TSO'd component.

And I think the answer is "no one." Everything is repairable or replaceable, including TSO markings. When a manufacturer or other expert says something is unairworthy, they are really saying it is economically unrepairable. How should we convey "economically unrepairable" to the owner? As important, how should we convey it to anyone else who comes into possession? The most concise way is to obliterate the TSO marking, by removing it or by writing "unairworthy" or "condemned" or similar on the label, words that are technically not true because it could be made airworthy if time and money were no object. I'm okay with that, but I'm open to alternatives.

It still belongs to the owner, though, and he should get it back in exchange for the agreed compensation for inspection, shipping, etc.

--Mark

-

1

1

-

-

3 hours ago, wolfriverjoe said:In general, nobody but the military goes above 50k.

Glider record is a little over 74K, although pressurized.

-

24 minutes ago, Bluhdow said:To have a product sitting on the shelf, the manufacturer most absorb the cost of the good well in advance of collecting the revenue. Investing a lot of money into something that might sell someday is not as efficient as dedicating resources to something which has already sold (e.g. orders).

I get that. But I don't think it's a lot of money.

-

1

1

-

-

1 hour ago, riggerrob said:While it would be ideal to stock one of every size of D-bag, it is just not economically feasible. Consider that some of those rare sizes will sit on the shelf until they are sold. No company can afford to have a huge stock sit on the shelf with slow turn-over.

I disagree. Harness/container manufacturers may have at most 8 or 9 different freebag sizes, and they can look in their records to see which sizes they have shipped separately from rigs. Ditto main bags. High-demand items should be available for immediate shipment.

Some have two reserve pilot chute sizes, most have just one. These should also be available immediately. If you have an exposed pilot chute (e.g. Racer, Javelin, etc.) it might make more sense to wait for orders instead of having some in stock, I'll bet many customers would be okay with basic black if they could get one right away -- the new colors aren't going to match the sun-faded colors anyway.

Likewise, they know what riser lengths they have been shipping. Running a few more for spares when you're making a batch anyway shouldn't be an issue.

Ripcords and cutaway handles are frequently custom, but most of our customers would be happy to have a metal-handle ripcord and a red cutaway pillow if it would get them back in the air by the weekend.Disclaimer: I am not a manufacturer, just a whiner. Perhaps someone who is can chime in to explain how scheduling and production work, and why having ready-to-ship spares ties up too much capital.

-

Some things to investigate:

Damaged area on bottom skin: along the seam? If so, maybe manufacturing, since these are relatively new canopies.

Color of the fabric? If always the same color, maybe a problem with that batch of fabric.

Location of the damage: center cell? end cells? right side? left side?

Where did the tear start? Adjacent seams with elongated stitch holes show greater stress in that area.

Burn or burst to start?

Sliders burned or burst?

What extra steps have packers taken in response?

-

40 minutes ago, Deisel said:They both have well established procedures for FAA examiners to regularly come out to conduct check rides in the local area.

Are these examiners FAA employees? If so, how are their travel expenses covered?

Or are they DPEs? If so, who is prohibiting them from traveling?

-

3 hours ago, riggerrob said:This relates to a question about FAA DPREs doing practical tests outside of the continental USA. Is that even an approved procedure?

Requests to test outside the supervising FSDO's geographical area must be approved by the FSDO that has appointed the DPRE and the FSDO/IFO (International Field Office) where the test will occur.

The test location must be approved, to ensure it is adequate for the test. This may require a site visit.

The FSDO/IFO where the test will occur may wish to observe the test, but I don't think such travel would be funded -- the IFO for Canada is in Houston, Texas.

I don't know of any DPREs who have tested outside the US.

Also, your applicants will need to submit an 8610-2 Rating Application Form to a FSDO, and because of St George, FSDOs are reluctant to accept applications from outside their geographic areas. Pre-Covid, applicants were required to appear in person. And there are a couple extra steps a DPRE must take before testing someone whose application has been approved by a FSDO other than the one supervising the DPRE.

Your applicants will likely also have to travel to the US to take their written tests.

Discouraged yet? It might be easier to move your course to the US.

-

I'm looking for contact information for the owner of Lone Star Parachute Company, also known as Parakit, Inc.

--Mark

-

34 minutes ago, wolfriverjoe said:I can fully understand the reluctance of a rigger to pack a reserve without a card

I cannot. The rig is either airworthy, or it is not. Airworthiness is determined by inspection of the rig, not inspection of the data card. What question of airworthiness can be answered by the data card?

-

2

2

-

-

When we did testing for the RI MOJO, every jump was an opportunity to lose the prototype device sewn to the reserve bridle. I added a pocket for a Tile, and it came in handy a couple times. No effect on packing or deployment. Of course, on a production freebag/bridle, this would be an alteration requiring FAA or manufacturer approval.

-

2

2

-

-

4 hours ago, Deisel said:I'm considering taking a rigger course this summer but don't plan to work as one. Primarily I'd be doing it just to increase my knowledge about the equipment.

Unfortunately, most rigging courses are focused on reserve packing proficiency, plus the small amount of additional knowledge required to pass the test for an entry-level parachute rigger.

If you are interested in how things work, how they are made and how they break, how to fix them when they break, you will need to be an active rigger. The way we learn and get better is by inspecting every rig that comes through the loft, evaluating the work done by the previous rigger and hoping to find something that is different and better than our work, then upping our game.

If all you work on is your own rig, you will be just a perpetual entry-level rigger. At best.

(Also, you will also always be legally uncurrent, although I don't know anybody who has ever been busted for that.)

-

2 hours ago, shadeland said:There's the maximum weight the gear has been rated at, and then there's the maximum weight that will put a canopy faster than 24 feet per second descent rate, 36 feet per second total speed (usually around 1.3 WL) which would be significantly below the tested load weight (i.e 254 lbs).

No. The descent rates are measured at the maximum operating weight. See AS8015B para 4.3.7.

why did kevlar lines go away?

in Gear and Rigging

The line sequence was:

Kevlar has poor abrasion resistance. It is also skinnier than dacron, so less friction in slider grommets and harder openings. Also, kevlar doesn't stretch much, so less shock absorption than dacron.