Leaderboard

-

in Articles

- All areas

- Adverts

- Advert Questions

- Advert Reviews

- Videos

- Video Comments

- Blog Entries

- Blog Comments

- Images

- Image Comments

- Image Reviews

- Albums

- Album Comments

- Album Reviews

- Files

- File Comments

- File Reviews

- Dropzones

- Dropzone Comments

- Dropzone Reviews

- Gear

- Gear Comments

- Gear Reviews

- Articles

- Article Comments

- Article Reviews

- Fatalities

- Fatality Comments

- Fatality Reviews

- Stolen items

- Stolen item Comments

- Stolen item Reviews

- Records

- Record Comments

- Record Reviews

- Help Files

- Help File Comments

- Help File Reviews

- Events

- Event Comments

- Event Reviews

- Posts

- Status Updates

- Status Replies

-

Year

-

All time

January 20 2016 - April 17 2024

-

Year

April 17 2023 - April 17 2024

-

Month

March 17 2024 - April 17 2024

-

Week

April 10 2024 - April 17 2024

-

Today

April 17 2024

- Custom Date

-

All time

Popular Content

Showing content with the highest reputation since 04/17/2023 in Articles

-

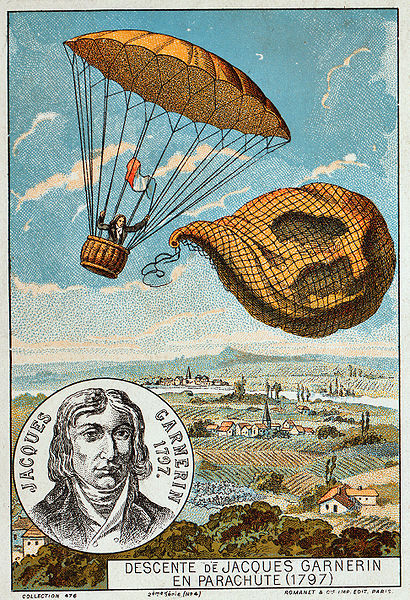

1 pointToday recognizes the 216th anniversary of the first parachute jump, made back in 1797 by French aeronaut André-Jacques Garnerin. Garnerin, who was born on the 31 January 1769 was a student of the legendary ballooning pioneer, Jacques Charles. Charles himself, a decade before Garnerin's record was set, set a record of his own when along with Robert brothers, he became the first to used a hydrogen-filled balloon for manned flight. Garnerin, no doubt heavily inspired by his professor, began to forge his own path in the aeronautics world, becoming the Official Aeronaut of France. France was undoubtedly the hot spot for aeronautic discovery and innovation in the 18th century, and in 1783 it was the Frenchman, Sébastien Lenormand who invented what is considered the first modern parachute. The original design that was used by Garnerin for the first parachute jump was naturally a far cry from what we are familiar with today. The parachute itself was made from silk and was approximately 23 feet in diameters. The device was constructed using rope to connect the basket to the edges of the material. Prior to ascent the parachute resembled a closed umbrella and consisted of a pole which ran down the middle, with rope that ran through the pipe. This was used to attach the parachute to the balloon that he would be ascending with. The occasion of the first parachute jump itself took place in Parc Monceau, Paris on the 22 October 1797. Garnerin made ascent to a height of around 3,000 feet, before cutting the rope that connected the parachute to the balloon, and in turn allowed him to begin his descent. The descent was anything but smooth and Garnerin had to deal with the basket swaying violently during the flight, as well as having what could be described as a bit of a rough landing, with the basket scraping along the ground. In the end though, Garnerin had successfully completed the first parachute jump and paved the way for modern parachuting. Despite the fact that Garnerin was the first to perform a manned descent with a parachute, it is worth noting that 12 years prior to this, Jean Pierre Blanchard had used a parachute with a basket attached to perform parachuting demonstrations using a dog as a passenger. While given the advances made in France each year in the latter part of the 18th century, it was inevitable that a manned parachute jump would occur. It was Garnerin who made it happen first and can in turn be seen as the first modern parachuter in the world. Google honored this anniversary by adding a parachuting game to the Google doodles. Be sure to go check it out!

-

Newsletter